CONTENTS:

Introduction

Preparation Work

Priming & Painting

Modding

Air Flow

Cable stealthing

Chassis modding

Finishing touches

Cable sleeving & Trim work

Assembly

Lighting

2015 Upgrades

2017 Upgrades

2018 Rebuild & Upgrades

2019 SSD Upgrade

2024 Rebuild & Upgrades

2024 Intake Fan Upgrade

2025 Graphics Card upgrade & bottom intake vent

2025 CPU upgrade, top panel I/O upgrade and drive cage removal

2025 CPU replacement and RGB Lighting

Introduction

For many years I wanted one of these cases, if not the whole system ( at the time they were top end systems, and even now current models come in a similar flavour of hardware to what I plan on using ). Anyway, fast forward several years and 5 computers ( 2 custom builds ) later and I finally managed to secure the case of my dreams; from Germany no less ( such is the difficulty in finding one- a money-can't-buy item nearly )...

That's the bulk of the hardware I will be using ordered ( I will put a full list & links at the end of the project ); I went for an i5 2500k SandyBridge as opposed to the newer IvyBridge equivalent due to heat concerns- I do plan on overclocking & don't plan on watercooling so a cooler running CPU which is still powerful as you like is the order of the day.

And in all her glory:

Yes, I am modding an Acer Predator ( G7713 model ). It was completely gutted at some point in the last 2 years and found its way onto ebay; oddly most of the bare cases I found for sale were in Germany, very rarely do they come up for sale in the UK it seems. Now, I know this case has a habit of splitting opinion quite strongly- many guys love the unique styling, others loathe it with a passion. I love it however, hence.

Preparation Work

The Acer badges had to go as I wanted a smooth front cover, so out came Mr. Stanley to carefully prize them both off- wasn't sure how they were secured but it soon became obvious- small through-pins that were melted on the other side once inserted to lock both parts together. With the badges removed I mixed up a batch of car body filler to fill in the holes they left, a slight pain as unlike 2 part epoxy resin in syringe dispensers you have to mix up the whole of both tubes here, though I managed to just use half & half in case I needed any more later on.

I did go a little mad with the amount I used- I was concerned it would contract and need another going over if I scraped it off level, so better to use too much and sand it down flush later.

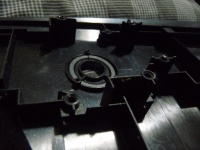

After that I went about stripping the rest of blue panels from the chassis & side panels, not too difficult as they are held in place mainly by small retaining clips which I carefully pried back and then unclipped. At this point I discovered the mechanism for slowing the opening & closing action of the front panel & arms; a spring loaded larger spur gear and smaller much stiffer pinion. Dreams of a motor operated front cover swirl around in my mind...

Priming & Painting

Unfortunately the left-hand side panel ( when viewed from above looking from the rear ) is fixed in place, and as such the plastic part of the side panel cannot be remove without drilling out the rivets & then replacing them afterwards. This is more hassle than it's worth so I elected instead to mask up the case and around the edges of the side panel and painted it in-situ.

I was planning on waiting until the end of the month ( payday ) until I purchased the Graphics card but it makes little odds really so I pulled the trigger a little sooner:

Modding

While the paint was drying I started work on the chassis, beginning with hiding the ugly plastic pattern on the top panel. I had chosen faux leather to work with as it has a nice textured finish & hopefully adds a touch of class. I started by making a cardboard template, then covering it with 5mm thick upholstery foam, then gluing & stretching the leather over the top to create a cushioned top panel of sorts.

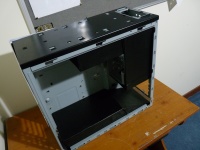

While the glue was drying I broke out the Dremel* and removed the SAS HDD drive cage and mounting parts- a job made much easier by my recent purchase of a Flex-shaft so that I could get into hard to reach areas with the cutting disc. At this point I discovered the recess I had created was the perfect size for a standard HDD to hide in, though mounting it would be rather tricky, so I stuck with my original plan of putting it in the 3.5" bay beneath the card reader. I also ripped out the tin-foil PCI-E slot covers as I have some steel ones I plan to use.

Air Flow

Since this case is rather lacking in ventilation ( a tiny mesh side vent & one exhaust fan ), I decided to open up the panel behind the front drive bay door to allow for better airflow ( I plan to mount an intake fan here too ). I dismantled the door and then set about marking up & cutting away as much material as possible without compromising too much strength, using the sanding drum attachment to tidy things up afterwards. It didn't need to be perfect as 99% of the areas I worked on are not visible under normal conditions- I did crack the clear plastic part but fixed it up again with some 2 part epoxy resin.

Cable Stealthing

Now work on the inside of the chassis beings in earnest. Initially I had planned on mounting the PSU in the bottom-front of the chassis to act an intake fan, but due to the large number of unwieldy cables ( not willing to void warranty on it by removing unused cables ) it just wasn't going to work, so instead it'll be mounted in the stock location at the top of the rear chassis panel.

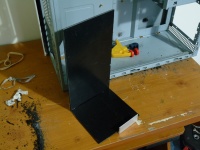

The cables still need to be hidden away however so I decided to construct a compartment for them in the top of the chassis, mounting it at one end to the upper 5.25" drive bay for support. I used aluminium L-channel & some ABS plastic with Carbon Fibre print on one side ( originally purchased for an R/C project I never bothered with ), cut & shaped it as required using a hacksaw and Dremel*, then set about covering it in yet more faux leather. I'm using leather on the inside of the chassis since I started with a 140cm x 100cm sheet of the stuff as that was the smallest size I could order, luckily it's very cheap so happy days.

Chassis modding

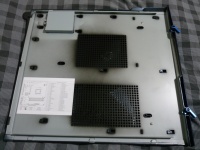

While that sticky mess was drying I got to work on the chassis again and ground down all the various little lumps & bumps that weren't needed any more & were getting in the way ( mainly quick-release related stuff, and since this case didn't have the quick release parts.... bye bye time ).

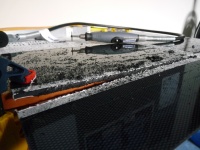

Went threw several of the non-reinforced cut-off discs in the process and made lots of dust, but in the end we have a much smoother drive bay enclosure & rear panel now. It doesn't look it of course, but where I have bent the small tabs back in line with the rest of the back panel & ground them down, they don't protrude on either side at all any more & with also get the leather treatment.

I also did a quick test-fit with the cable enclosure and it fits fine, very tight but it ain't going anywhere; I also had a brainwave and realised I could grind the upper edge of the rear ( PSU ) support it sits on in order to make it sit level properly, so that'll be for tomorrow along with making the drive cage enclosure hopefully.

I'd been pondering for a while if a 120mm fan would fit in that opening ( originally for the SAS drives ), and as luck would have it with a little bit of dremeling they fit perfectly. Securing it in place required a little bit of thought but you'll see that later.

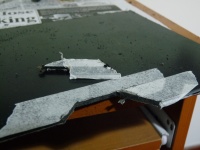

Knocked up a drive bay cover using more ABS plastic & L- channel aluminium + epoxy, quick test fit & everything is fine there. It will be secured from underneath using a couple M3 ( 3mm ) dome headed screws and nyloc nuts.

Now, the mounting holes for a M-ATX mobo were all in place, but not all were threaded, so I had to spend 5 quid on a 6/32" tap for the sake of tapping two holes ( tried just forcing the stand-offs to cut their own thread but no joy with a steel chassis- aluminium maybe.. ). One hole was right next to the back panel so I used a pin-vice & some pliers to turn the tap instead.

Now for the last piece I had to construct for the inside of the chassis ( hopefully ), the 'sort-of mid-plate'. Not a true mid-plate as it isn't hiding the PSU or a radiator, but it does hide all the front panel wires and serves a more important purpose, that is, to channel the airflow from the front fan up towards the GPU & CPU cooler. As I ran out of epoxy making the drive bay cover, I had to use the next best thing I had which was JBWeld.... and some left over car body filler... The slot in the top is for the front panel connectors to feed up through.

Test fitting all three interior pieces, worked out just great in the end. With the mobo & PSU installed there will barely be any bare metal exposed around that area, just the rear panel & front panel areas to cover mainly and I have plenty of faux-leather left. I purchased 3 different sizes of P-clips for cable routing, just got to plan my routes as it were and then drill & tap some holes for them.

Due to how the cover plates cover mounting holes and such, it has become apparent that I will have to assemble the guts in a certain order which will be loads of fun I'm sure....

Finishing touches

Bit more leather work to fill in a gap- will need to redo the trim piece in one long strip though. Rear fan grill had to go too, mixture of dremel & hacksaw work which was surprisingly tough on a ~1.25mm steel chassis. New fan grill filter is rather nice- is made from magnetic rubber with a fine nylon mesh, so no need to stick it down ( easily removable for cleaning ).

Remember that metal tab I bent back ( yeah you do.. ), well, that was for cable routing; no space behind the mobo, but just enough down beside the drive cage to feed the font panel connections. Those will also be held in place by the P-clips I bought, as will the power & data cables when I come to install the electronics later on.

It's coming along nicely at the moment- few bits here & there to do & redo on the leather as I said earlier, and I had to tweak the top panel cover as I didn't account for the white plastic piece straddling it quite so closely at the rear end ( ooh err.. ). Fan was held in place with some carefully placed zipties; barely visible unless you look closely ( there is another magnetic fan filter placed behind the fan ).

Left to do:

(Re)apply leather trim where needed- rear fan hole, drive cage, front fan hole, slot in the sort-of bottom-plate.

Sleeve cables ( visible sections ).

Install cable routing clips- mainly on the fly depending on how compliant the cables decide to be.

Install components & cover pieces.

Hit the power button & hope for the best...

Cable sleeving & Trim work

Sleeving, sleeving & more sleeving. Unfortunately the rear magnetic fan filter ( a filter on the exhaust?, seemed like a good idea at the time... ) was just a tad too big to fit with the side panel fitted, and trimming it would ruin it really, so I went with option 2 and a standard wire fan guard instead. I also gave up trying to make the leather piping trim go around the inside corners of the cut out ( outside bends are easy, inside bends is a no-no, especially 90° ones & where the flange of the leather is visible ) and went with rubber U-channel instead. Couldn't make the U-channel fit on the front intake cut out though due to there not being a large enough gap on the outside edge ( between the panel and the fan ), so a Sharpie was deployed to disguise the white edge of the faux-leather. Not quite what I wanted but no one will ever see inside this case once it's assembled, mores the pity.

Tomorrow I pull the pin & start fitting components, cable routing, and if it doesn't get too late ( early start required ) yank the heatsink & HDD + ODD from my current rig and transplant them over, then fire up the new rig and see what happens.

Wish me luck...

Assembly

Remember what I said about needing to assemble this in a certain ( unknown ) order, in order to make everything fit? Yeah, took a lot of head scratching, cursing & a couple attempts to tame Electronic Lord Cthulhu before I figured that I had to install the PSU before the PSU-wire cover plate. With that fitted & sleeved extensions ( turns out I didn't have any sleeved sata power cables, so just using the lead on the Seasonic PSU ) routed down through the notch, I started tearing into my current rig to pull out the HDD & ODD, along with the mobo speaker. Next up I checked over the socket on the new mobo to look for bent pins with a magnifying glass ( none found ), then installed the lovely new ram, CPU & mounted the venerable old Titan Fenrir ( which does an even better job in it's new home.. ) using the new retention bracket thingy. The only odd thing there was that I didn't ( couldn't ) need to use a back plate for the CPU cooler, it simply held in place from the rear with screws and washers- very solid and no mobo flex so I'm happy enough with that setup ( forgot to take pictures of those steps unfortunately ).

Next up I had to wrestle the mobo into the case, whilst trying not to get hooked up on the various front & top panel connections sticking up through the sort-of bottom plate ( like trying to fit an ATX mobo into an mini-ITX chassis... ). I got that done and started connecting up the various leads, only to find I needed one more usb 2.0 header than the mobo had available, but I do have a usb 3.0 header to put to use so more on that later. As luck would have it, or not, I didn't need to use any of the cable routing P-clips since the leads seem to have organized themselves almost perfectly thanks to the very short runs they make from A to B; I'll be selling the P-clips and loads more stuff from the old rig i the next few days so keep an eye out in the Sales section.

Anyway, with everything connected & double checked, I plugged in all the external leads, turned on the PSU & hit the power button; she lives! I entered the UEFI Bios and had a quick poke to set up the boot options & what-not, then exited to see if she would start up normally. Alas, my fears were borne out as she kept blue screening as soon as the windows logo / animation began. So, fresh install of Windows 7 Pro x64 and several hours of updates & downloading programs and I'm back up and running with my shiny new machine.

I've tested out the 670FTW graphics card by playing several sessions of Hawken with all settings turned up to Ultimate & set for 1920x1080, max temps are around ~75°C with the fan not going over 40% ( barely a quiet hum ), not too shabby really. Frame rates are kinda hard to track as it's a live-view chart in the EVGA Precision-X software, though generally looks to be anything from ~40fps upto 110fps+ depending on how much action there is on screen. I'm not a bench-marker really so I'm more than happy with the image quality & frame rates I'm getting, well worth the cost. Windows Performance Index reports scores from 7.5 to 7.8 for everything apart from the HDD ( 5.9 ), so that's great too.

She isn't done quite yet though- still waiting on something special for the interior lighting ( which will be visible, despite the lack of case windows ), a few cables, and the side panel + front panel need to be repainted ( again, groan ) as they have magically picked up some nasty dirty marks from no-where whilst being carefully stored.

Once those 3 things are sorted I will take some final pics and post up a complete parts list break down for those interested.

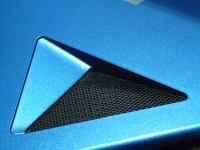

Lighting

There wasn't an awful lot I could do for interior lighting, given that the case is more or less sealed with only a small vent on one side panel. I could however do something with the 'grill' on the bottom of the front panel where the intake fan is located- I went to Ebay and grabbed a pair of 'Angel eye' LED rings intended for use as daytime running lights on car head lamps. I kept one as a spare, and the other I installed behind the intake fan to shine through the blades as they spin- worked rather nicely I reckon. They are connected to a fan controller on spare PCI slot on the back panel so that I can adjust the brightness- they really are rather bright on 12V so I turned them down a little to reduce the glare.

Now all I have to do is sort out some final pictures, but I'm kinda hoping Canon will release a/the 7D mkII ( in response to Nikons new D7100 ) before I do so, but I could be waiting months for that to happen, so I'll see what I can do in the next month hopefully to finally draw this project to an official close.

2015 Upgrades

I never did get any final photos, though I did give up waiting for a 7D MkII- took another year or more and wasn't enough of an upgrade to be worth getting, compared to a good used 7D which I did end up buying. Anyway, 2-3 years pass and I've been playing less Hawken, and started playing Space Engineers; anyone who has played SE knows it is a very demanding game, and my 'old' GTX670 card just wasn't cutting it. Therefore, I decided to upgrade to a GTX980Ti, and needed to get a new power supply to go with it. At this point, I decided to go with a Hybrid-Modular PSU, that way I didn't have to deal with the awful mess of power cables that I didn't need, just plugging in the ones for the HDD, CD-ROM, MOBO and Graphics card- so much tidier. The supplied power cables aren't all that sexy, being just plain black insulated leads, but they will do fine for me- the power rating is also a little higher, jumping from 620 to 750 Watts. Beyond that, I'm looking at maybe a Blu-Ray drive, and in the next year or so a whole new MOBO, CPU & RAM, since the 2500K is getting a little long in the tooth now.

2017 Upgrades

Well, I wasn't lying about doing some big upgrades, just not as big as I had planned; I had intended to go with something like the i7600k & 16GB of DDR4 RAM, with a sexy SSD and various other bits, but it seems that it took AMD far too long to come up with a decent CPU resulting in Intel getting lazy. The upshot being that it would hardly be worth the expense and effort to build a new PC when it wouldn't be vastly more powerful than what I already have ( the SSD and faster RAM making the most difference realistically ); it seems however that AMD did give Intel a kick up the backside so we can expect to see some truly up-grade

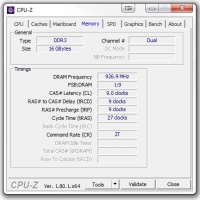

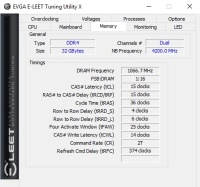

worthy new CPUs in the next couple of years. In the mean-time though I have been doing more video editing and my rig does chug somewhat with that kind of task, so I said screw it and decided to pick up a better CPU that I could use with my existing system, upgrading from an i5 2500k to an i7 3770k, along with an upgrade from 8GB of 1600mhz RAM to 16GB of 1866mhz RAM ( Space Engineers eats RAM for breakfast, as does Google Chrome... ). The difference in video editing is very noticeable, much quicker to export video/render finished projects now, and I can get back a large chunk of the cash I spent by selling my old CPU & RAM- seems CPUs are holding their value remarkably well, and RAM prices have gone through the roof for some reason.

I do still plan on building a more or less complete new system, but I doubt it will be for a while now- I'd be more inclined to chuck an SSD into the mix at some point soon to bring my current rig upto date, for what I use it for generally this would tide me over for several more years...

2018 Rebuild & Upgrades

That was the plan anyway- seems like my PC had other ideas; a few weeks ago ( July 2018 ) my PC died on me without warning. One minute it was fine, the next it started behaving oddly, taking nearly two minutes to move from one folder to the next- I shut it down for the night, but in the morning it wouldn't boot, no error codes, no bios screen, just spinning fans and nothing else.

I was faced with a couple of options neither of which I liked- either buy a whole bunch of compatible parts and try to trouble-shoot the issue ( I didn't like this option as it means ending up with a ton of parts I might not need, old parts at that ), or just bite the bullet and go ahead with the big upgrade ahead of schedule. I took the latter option and begged my bank account for forgiveness.

Since this wasn't just an upgrade but more or less a full rebuild I gutted the chassis and also yanked out the LED ring light & its controller, yanked the front panel audio cable ( who uses that when you have an optical output on the rear IO? ) and finally yanked the whole CardReader since it was only USB1.1 speed. This reduced the number of cables inside the Chassis rather significantly and tidied things up a lot- a fact compounded on thanks to the new EVGA Z370 Micro using a side-mounted power connector for the 24-pin cable; this makes such a difference for cable management, along with a USB3 header that isn't in the middle of the board ( not currently using it but all the same ).

The only real gripe I had was having to trim down the CPU cooler bracket for my venerable old Titan Fenrir- there are a couple little protrusions in each side that fouled the Mobo heatsink next to the socket and were very close to the RAM on the other side, so I filed them down to give me the clearance I needed- other than that, installing the new system into the customised Acer Predator chassis was a breeze. I especially appreciate other little touches on the Mobo such as the on-board speaker and Bios code readout- the black colour scheme also looks very nice whether you have a windowed case or not.

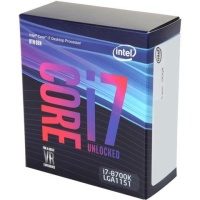

As for the actual upgrade parts, I went with the EVGA Z370 Micro motherboard as mentioned, the Intel i7 8700k processor, 32GB of Corsair 2600Mhz DDR4 RAM ( RAM, Y U so expensive? ), a 2TB Seagate HDD and a 120GB SSD from SK hynix- probably should have gotten a 240GB but never mind, we'll see how it goes. I also took the opportunity to upgrade my back-up storage, going from the 500GB WD MyBook to a 4TB version with USB3. I kept the same PSU and GFX card since both work perfectly fine and are still more than adequate for my needs- when the next generation of cards comes out I expect we will see an abundance of 1080s and the like flood the market, especially if the crypto mining bubble starts to burst, then I might pick one up at a sensible price.

Anyway, the rig is rebuilt with up to date parts and the performance is great, I even upgraded to Windows 10; works very much like 7 so not too much to adjust to, though there are a few minor quirks but that's the same with any new OS really so I'm happy enough- some of the new features required 3rd party software in the past so that's certainly a welcome improvement, and having the SSD as the boot drive makes a world of difference to start up times and program responsiveness. This time, I really don't plan on any major upgrades for at least 5 years or more, with the GFX card being the only likely component that gets swapped out for something newer. See you around...

2019 SSD Upgrade

It turns out that a 120GB boot-drive was wishful thinking- large enough for the programs and OS, but as soon as I started doing any video recording the drive filled up very quickly and I started getting warnings about being low on space. As it happened there was a sale at Scan so I decided to pick up a nice M.2 SSD drive- 512GB for less than 90 quid, the only issue being the pain in the ass that is removing the graphics card in order to install the tiny drive directly onto the mother board; I hate the retention clips that are near impossible to access and won't release the card unless they are fully opened ( which you can't do easily with a huge card installed ). Regardless, I wrestled the card out and installed the SSD, then set about cloning the Boot drive

with the software from EaseUS designed for just that procedure- didn't take too long and was very simple to follow the instructions. The new SSD is very quick- not the fastest but then again I'm not really a fan of willy-waving and upgrading every few weeks when new gear is released, 1500/1000 read and write is plenty for my needs. I did also leave the old 120GB card installed since.. why not? It might be useful for something one day and its re-sale value is pennies; the price of SSD is really dropping fast lately which is great news for people upgrading and building new rigs, although it is a little irksome for those of us that purchased drives only to see them appear for 25% less a few months later- amusingly enough however pretty much everything I bought

when rebuilding the PC last year has gone UP in price- swings and roundabouts as they say...

2024 Rebuild & Upgrades

It's been 5 years and my PC decided it was time to start randomly bluescreening- every time I booted it up; yay. Well, given it was getting a little long in the tooth I decided it was time for a rebuild and upgrade, so I spent a few weeks researching and agonising over my options, AMD vs Intel, and finally opted on a 13th generation Intel build.

I went with an i5-13600k, Asrock Z790 Lightning mobo, 32GB of fast 6000mhz DDR5 ram, a 4TB Lexar NM790 M.2 Drive, a Thermaltake anti-bending CPU bracket and a new internal card-reader to replace the Lexington external one that lived on top of the PC case.

I reused my beloved Acer Predator case, EVGA 750watt PSU and rather old 980Ti GPU ( I'll update that one day, maybe )- I had to cut a hole in the front panel of the case so that the new card-reader could slot in where the original lived, nothing that a rotary tool and a steady hand couldn't take care of and the result looks pretty clean.

I also recycled my equally old Titan Fenrir CPU cooler as it still fits the mounting pattern of the LGA 1700 CPU socket- thankyou Intel, lol. I am conscious that even with a semi-modular PSU the wiring could do with a little tidying up, shorter cables would certainly help though they aren't all that cheap and since there is no window I hardly see the point- I'll live with it as it is.

Performance is great, noticeably quieter without a HDD and much, much faster in video rendering and opening programs and saving files.

On a side note along with the blue screens on the old system I was also having an issue with an unknown USB device malfunctioning- I thought it was the mobo but I still had the same issue on the new system;

via process of elimination it turned out to be the front panel USB hub built into the top of the case- disconnected it from the mobo and the problem is gone. I think I might do some more modding at some point to remove the old circuit board and mount a USB3 hub in its place- again, nothing that a Dremel and some glue can't fix. When I can be bothered that is...

2024 Intake Fan Upgrade

It's a few months in and I have noticed that the new build does tend to get a bit warm, especially under load so I decided to do a little bit of case modding in order to add a larger intake fan; compared to any modern case the old Acer Predator is extremely lacking which is why I added a 120mm fan originally, but now we need a little more cooling so it's time for a 140mm fan. Not too much work required,

just a little bit of hacksawing to enlarge the opening, and a little bit of drilling so that the larger Corsair 140mm fan can fit without obstruction to airflow. I also took the opportunity to shift the optical drive to the higher mounting spot to give a clearer air path for the CPU cooler, deleted a fan extension lead, and tidied up the other wiring rather a lot including cutting down the daisy-chained Sata power connector

to just have one connector instead of three for the optical drive. Looks much cleaner inside the case now and airflow is improved- not sure how much difference it really makes though since I never recorded any before and after temperatures, so we'll just pretend it was worth the couple hours of work and call it good...

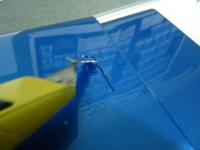

2025 Graphics card upgrade & bottom intake vent

I love my EVGA 980Ti, it has been with me for 10 years and several upgrade cycles, but now seemed like the time to upgrade finally. I wouldn't have bothered given the silly prices of GFX cards lately and the lack of performance uplift from the previous generation, but as it happens I sold a camera lens I wasn't using anymore and had a good payday at work, so this month was likely the only time I could upgrade without it even making a dent in my savings ( line goes up = happy Neil ).

The lack of performance increase from the previous generation was of no concern to me given my current card being 10 years old, anything would be an improvement at this point, so I agonised over my options for a week or two and went with an ASUS RTX 5070 Prime OC model. Why not a 5070Ti? Well, two things- price, and my performance requirements. The Ti models are anywhere from ~200 to 500 quid more expensive, and aimed at 2K or 4K gamers; I only have 1080p monitors and the next one I buy will be 1440p high refresh rate, so the 5070 is perfect, no need for a PSU upgrade either.

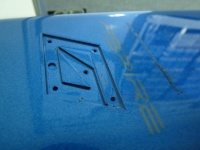

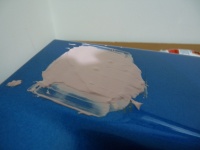

The one thing I did decide to 'upgrade' is the cooling, by cutting a 12cm square hole in the bottom of the Acer Predator chassis and putting a magnetic filter over it, or under it I suppose. This allows the GFX card to intake fresh air with its fans more easily- I wouldn't mind doing some more extensive mods to move the internal card reader higher up ( mount it in one of the CDROM bays ) and allowing me to have a second intake fan on the front of the chassis for even better airflow, that will have to wait until the next rebuild in ~5 years time or so...

2025 CPU upgrade, top panel I/O upgrade and drive cage removal

As mentioned on the News section of the Home page, my i5-13600k started dying on me due to the dreaded 13th/14th gen instability issues, so after sending that back to Scan.co.uk they confirmed it as faulty and I got a i5-14600k as a free replacement under RMA, which was nice. While I the PC stripped down I decided to do some work removing the old drive bays and the CR-ROM drive itself as I never use it these days, and that would free up some space at the front of the case to make future upgrades/rebuilds easier.

I did drill out most of the rivets but there were a few that were impossible to get to , so I had to opt for some Mole-grips and violence to rip out the drive bay frame- worked like a charm with no damage to the chassis. This did mean however that I had to glue the card reader in place but that's fine, it's not going anywhere unless I hit it with a hammer which I don't plan on doing.

During reassembly I remembered that I wanted to replace the dead top panel I/O, so I purchased a simple 2 port USB3 drive bay adaptor and cut away most of the metal to make it smaller, gluing the remaining important part to a panel of ABS plastic that I cut and sized to fit in the opening in the top of the case once the old I/O 'bump' had been removed- hardest part of that process was drilling and filing the two little rectangular openings for the USB sockets to line up with ( it's not perfect but close enough for me as always ).

That got plugged into the motherboard USB 3 header ( there are two, which is rather handy ) and then stuck in place with some double-sided tape, giving a flush fit with the rest of the top panel and looks great, very clean looking and easier to plug things in compared to the old angled sockets. Hopefully nothing else goes wrong or breaks, I don't expect so but you never know with electronics- I do have some LEDs coming for the inside of the case as I want to have a subtle red glow coming out the front, feels a bit bland with only the power indicator for lighting.

I don't want crazy RGB rainbow effects as there are no windows in the case and it looks distracting to me, just a gentle red glow- I'll cover that in a new update once they arrive and are installed...

2025 CPU replacement and RGB Lighting

Well, that didn't last long- less than 3 months and my replacement 14600k went to silicon heaven too just like the last one and also had to be replaced under RMA ( thanks Scan, again ); I have no faith in the replacement so if this one also conks out I'll see if I can replace it for a 12th Gen CPU, one way or another. Anyway, since I had the PC torn down, I took the opportunity to install the new RGB lighting- one strip coiled up and stuck to the roof of the case, the other wrapped around the card reader, and all the cables routed... somewhat neatly ( I have thoughts about improving the cable routing though in all honesty it's not that bad, and custom shortened cables wouldn't really help that much either ). The pictures aren't great for obvious reasons, but you'll get the idea- there's a nice red glow out of the vents on the front, the former CDROM drive area, and the small vent on the side panel, it's fairly subtle but a nice touch.

|